Since the beginning of the 21st century, people are increasingly looking forward to the era of solar power generation under the serious impact of the two major crises of bottoming out of oil exploitation and deteriorating since ecological environment.

[1] Solar energy is an inexhaustible source of renewable energy for mankind, which does not generate any environmental pollution. Photovoltaic is one of the fastest growing fields of research in recent years.

[2] To this end, people developed solar cells. There are many types of solar cells, such as crystalline silicon solar cell, amorphous silicon solar cell, GaAs Solar Cells and Perovskite solar cells, etc. Silicon solar cells play a very important role in the photovoltaic industry.

[3] Crystalline silicon solar cells occupy the dominant position in the solar cell market. Its preparation technology represents the preparation technology of the entire photovoltaic cell industry. Traditional crystalline silicon solar cells consist of silicon, the main part of the solar cell is fragile and easy to produce invisible cracks. Most of them have a layer of toughened glass as protection, resulting in heavy weight, inconvenient portability, poor seismic capacity, high cost. Thin film solar cells overcome the above shortcomings but with lower efficiency. Thin film silicon solar cells become increasingly important because high efficiency and low manufacturing costs of photovoltaic cells both need to be taken into account at the same time. Light trapping is a vital factor in the development of thin-film photovoltaic devices. Cell performances reduce with the active layers becoming thinner. One approach to enhancing their light utilization efficiency is to reduce the reflection of the incident light by front surface modifications. Until now, a number of proposals have been taken to achieve the goal, including anti-reflective coating and surface texturing. First method is to reduce the reflection on front surface. Second method increases the optical path length of light within the cell. For the former sort, reducing reflection on the surface via introducing the quarter wavelength antireflection layer has been proposed. Certain intermediate materials are usually used, such as silicon dioxide (SiO$_{2}$),

[4] silicon nitride (Si$_{3}$N$_{4} $),

[5-6] and other transparent conductive oxides.

[7] The second category is to construct surface texture ranging from random arrays to regularly arrays for more lights scattering or gain light scattering from noble metal nanoparticles that are excited at their surface plasmon resonance. The scattering may availably enhance the light absorption in thin film solar cells. For the first method, different materials have been studied for simulated results show that, an individual antireflection film in solar cells at the beginning. Then multiple antireflection films also have been investigated. As for the second method, a great number of nanostructures or metal nanoparticles

[8-11] were proposed to increase light absorption, such as constructing photosensitive materials into arrays like nanoparticles,

[11] nanowires,

[12-15] nanoholes (NHs),

[16-22] nanocones (NCs)

[23] or introducing surface plasmons. Later combination methods show better results have been proposed,

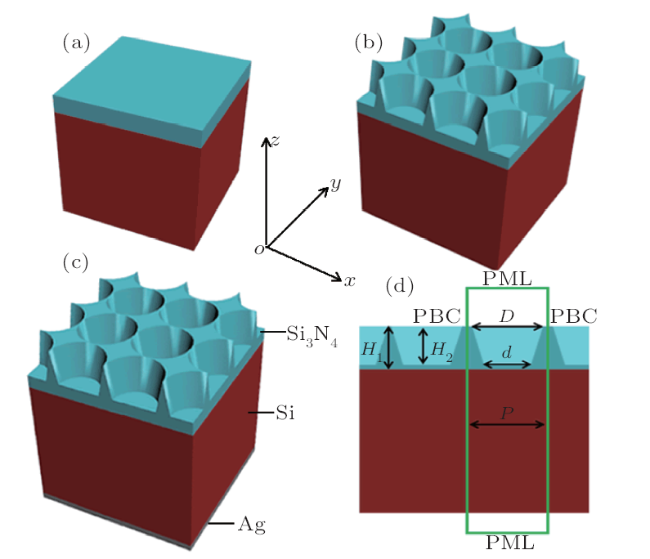

[24-26] In most of the articles, the researchers used the experience of predecessors to construct the surface morphology (make more light reflection happen) directly on solar cell material or to add multiple anti-reflection layers (make more light enter the cell) on the material. In this article, we combine two approaches to adding a textured anti-reflection layer on the surface of a solar cell to make both light reflection and anti-reflection happen at the same time and further produce optical coupling. The structure can be easily achieved by using nano-imprint lithography.

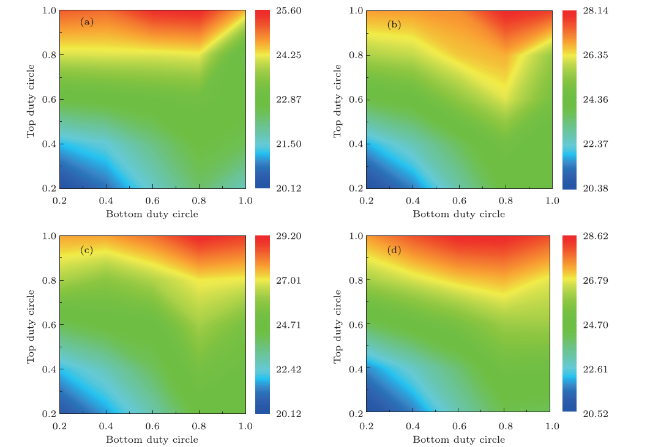

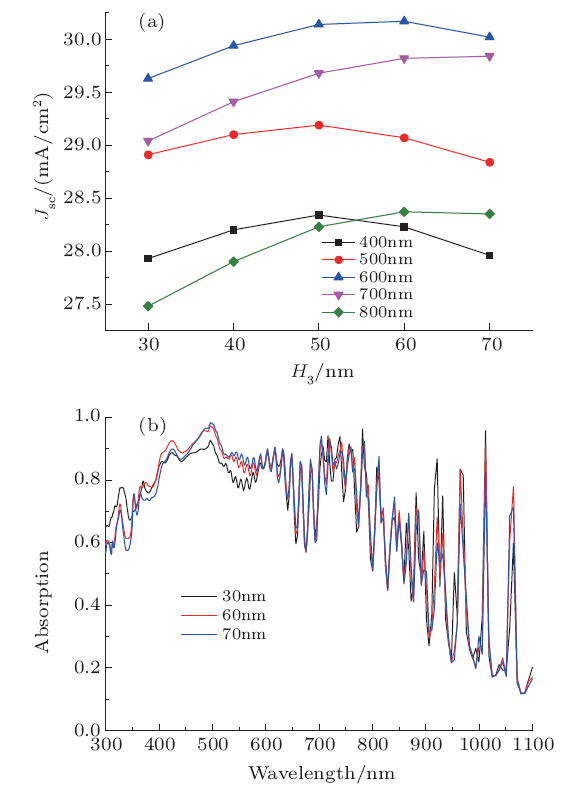

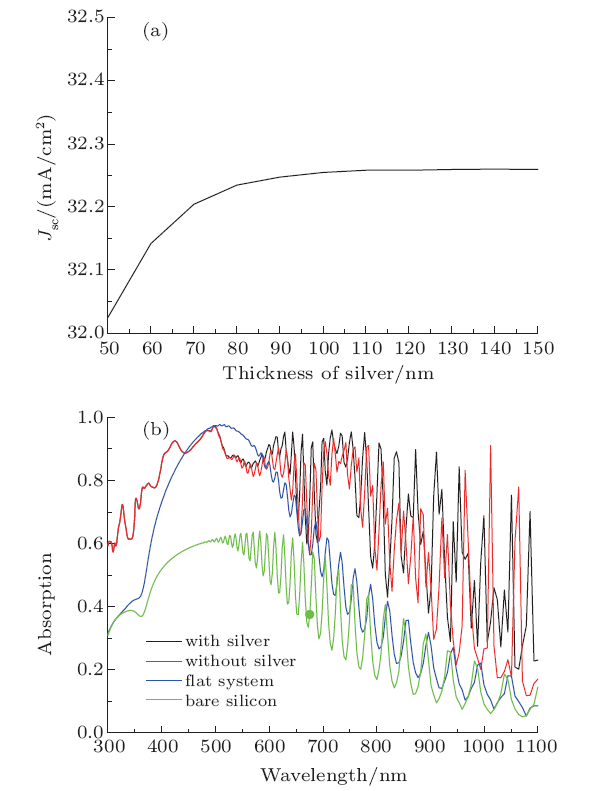

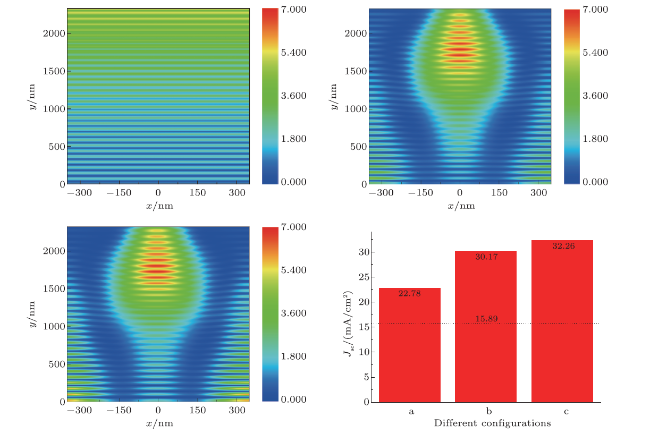

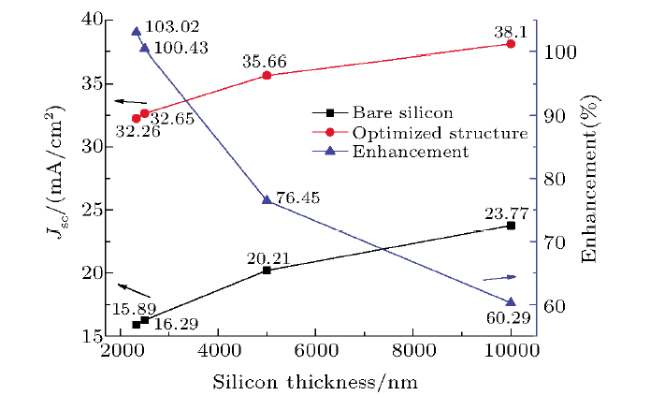

[27] We systematically studied how the depth of circular truncated cone holes (CTCs), antireflection layer's thickness, duty circle, thickness of silver and period affects solar cell's short-current current density ($J_{\rm sc}$) character. Simulated results show that a $J_{\rm sc}$ of 30.17 mA/cm$^{2}$ was produced in optimum parameters at an equivalent thickness of 2330 nm, produces an short-circuit current enhancement of 32.44% with respect to the planar reference system in the range of 300 nm to 1100 nm. And with a silver rear reflection equipped, the $J_{\rm sc}$ and short-circuit current enhancement mentioned above can be achieved to 32.26 mA/cm$^{2}$.