Figure

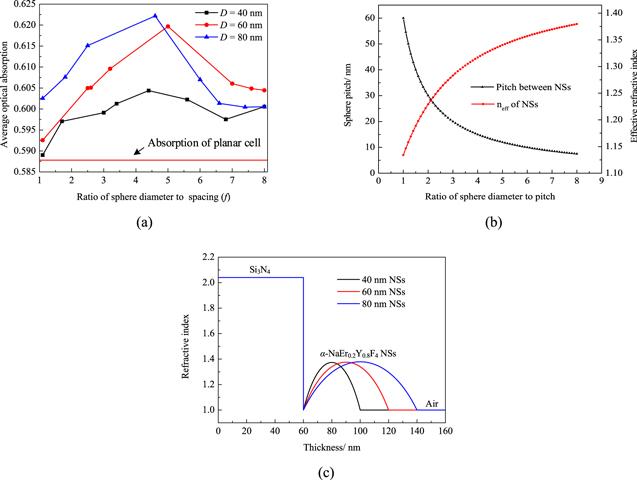

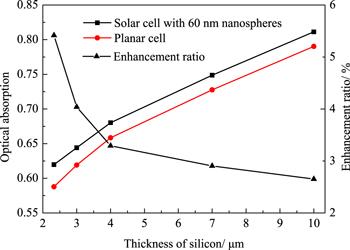

3(a) shows the influence of ratio change to average optical absorption of the SCs. The performance of SCs patterned with

α-NaEr

0.2Y

0.8F

4 NSs is obviously better than that of planar SCs with the same silicon thickness. From figure

3(a) we can see that when the ratio changes from 1 to 8, the average optical absorption of SCs with NS arrays on the surface increases at first, and then after a maximum peak appears the average optical absorption decreases. SCs patterned with larger NSs perform better in average optical absorption than the smaller ones. The highest average optical absorption and short circuit current density is gotten by SCs with NSs of D in 80 nm and

f in 4.6, reaching to 62.22% and 27.23 mA cm

−2, respectively. The results can be explained via the combined effect of the effective refractive index (

neff) change on the surface and excitation of optical resonances [

24,

25]. Referring to the effective medium theory, the high reflection originates from the mismatch between the refractive index of the air and SCs [

26]. When the NSs are patterned on the surface of SCs, it will bring forth the gradient change of the refractive indices and ease the mismatch between the different materials [

16], thus the reflection on the surface was reduced. Reducing the pitch between the NSs will change the filling ratio of nanostructure arrays, which has an effect on the

neff of the interfaces between air and SCs [

27]. The

neff of NSs is got from calculation formula [

27] at wavelength of 500 nm in 60 nm diameter NSs, shown in figure

3(b). In this wavelength the refractive indices of air and

α- NaEr

0.2Y

0.8F

4 can be seen as 1 and 1.5, while the refractive index of Si

3N

4 is 2.04. From figure

3(b) we can see that when the value of

f is small, numerical variation has great influence on

neff and sphere pitch. But after

f increases to a certain degree, the influence of

f changes on

neff and sphere pitch decreases. Therefore, the absorption enhancement when

f is between 1 and 5 in figure

3(a) is mainly due to the rapid increases of the

neff of NSs, which enhances the gradient change of the refractive indices on the SCs surface, and significantly reduces the light reflection. However, when the pitch of the NSs is small enough, for the 60 nm NSs less than 10 nm, the

α-NaEr

0.2Y

0.8F

4 dielectric NSs can be seen as a layer of dielectric thin film [

28]. Referring to Fresnel formula, the reflectivity can be derived from

$R={\left(\tfrac{{n}_{2}-{n}_{{\rm{eff}}}}{{n}_{2}+{n}_{{\rm{eff}}}}\right)}^{2}$ [

25]. For our model,

n2 is the refractive indices of Si

3N

4 and

neff is the effective refractive index of NSs. From the equation, if

neff of NSs continually rise with the increase of ratio

f while

n2 remains constant,

R on the surface of SCs will increase, causing the average optical absorption decline. Figure

3(c) shows the

neff variation of interfaces between the Si

3N

4 layer and air caused by different diameters of NSs. From figure

3(c) we can see the gradient

neff change on the top surface of SCs, which could reduce the light reflection. Larger sizes of NSs have gentler

neff changes for it can be regarded as a thicker dielectric layer and has better performance in light trapping than the smaller ones, which leads to higher absorption of SCs.